SCALE MANAGEMENT

Scale deposits can build up on the exposed surfaces of electrical submersible pump (ESP) components and production tubing, causing early pump failure and production constraints. Initial ESP system design is the first defense against scale. Selecting right-sized systems to avoid excessive pressure drop is your first line of defense. Assuming you have the optimal ESP design for the well conditions, Novomet offers two economical approaches to fighting scale—one using protective coatings to prevent buildup and one using chemicals to keep scale from forming as fluid passes through the ESP.

BENEFITS

Chemical and coating solutions can increase system runlife by 2.5 times in high-scale conditions

Downhole dosing units reduce costs compared to other scale prevention techniques

Dosing units and coated equipment are easy to install, requiring no special tools or teams

applications

- Wells prone to scaling

- High water concentration in downhole fluids

- Extremely corrosive conditions

capabilities

- Self-contained downhole solutions

- Maintenance-free operation

- Timed inhibitor release and long-lasting surface coatings

features

- Solids dosing technology releases granulated scale inhibitor while also enabling it to dissolve in reservoir fluids to improve dosing accuracy

- Liquid dosing technology delivers consistent scale inhibitor release over the life of the well

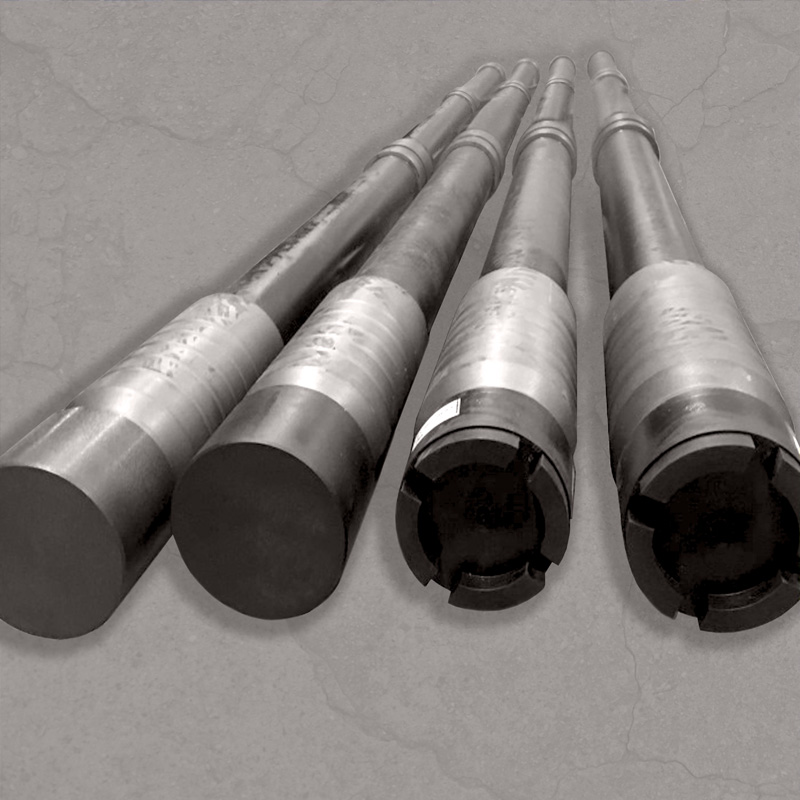

- Scale protective coatings prevent scale deposition on impellers, diffusers, and other ESP components

Scale Management with Downhole Dosing Units

Dosing units are installed with the ESP, providing one of the most effective and cost-efficient solutions for preventing scale deposition. We offer two types of units—one for dispensing solid scale inhibitors and one designed for liquid scale inhibitors.

For solid inhibitors, tubes in the dosing unit are filled with the inhibitor and a calibrated port is installed at the bottom of the tube. During ESP operation formation fluid flows into the downhole unit through perforations. The solid scale inhibitor is dissolved and gets mixed with the formation fluid. The dissolved inhibitor molecules are absorbed on crystal-forming nuclei, preventing scale growth and deposition on ESP impellers, diffusers, and equipment surfaces.

For liquid inhibitors, the unit includes a tube filled with encapsulated liquid inhibitor and a metering port. The number of sections is sized according to the well flowrate.

Encapsulated liquid scale inhibitor is contained inside capsules made of polymeric semipermeable membranes, usually sized between 50 and 100 mkm. The formation fluid flows through the metering port into the dosing unit, flows across the capsules, and dissolves the inhibitor as it passes through. The dissolved inhibitor leaves the unit through the metering port and goes to the pump intake. In the tubing inhibitor, molecules are absorbed on crystal forming nuclei, preventing scale growth and deposition on ESP impellers, diffusers, and equipment surfaces.

TECHNICAL CHARACTERISTICS

|

Outer diameter |

Inhibitor type |

Fluid temperature |

Flow rate |

Water |

|

3.5 in. 89 mm |

Solid |

149-167°F, 167-250 °F 65-75 °С, 75-120 °С |

1250 bbl/d 199 m3/d |

Up to 90 % |

|

4.5 in. 114 mm |

Capsules |

Up to 338 °F Up to 170 °С |

1250 bbl/d 199 m3/d |

Up to 100 % |

|

4.5 in. 114 mm |

Liquid |

Up to 338 °F Up to 170 °С |

1250 bbl/d 199 m3/d |

Up to 100 % |