DUAL ESP PRODUCTION SYSTEMS

Dual ESP production systems are capable of pumping reservoir fluid from two separate zones simultaneously in the same wellbore. This enables operators to isolate and measure production from two separate zones in multizonal completions. A modified version of the same basic technology can be used to inject fluid into one zone and produce from another in the same well. This enables operators to enhance returns by using water flood techniques without having to drill a separate offset well.

BENEFITS

Two complete ESPs enable production and monitoring of two separate target zones

The injection pump and the ESP enable EOR without having to drill a separate offset well

Dual ESPs and injecting-while-producing configurations can help recover more oil per well

applications

- Conventional wells

- Wells with two formation communication zones

capabilities

- Casing sizes that are 5¾-in. (146-mm) or larger

- Produce and monitor two separate zones, or use one zone for injection and one for production in a single wellbore

features

- Systems include all components (packers, pumps, motors, and other required equipment)

- Flexible configurations enable a wide range of solutions

Dual ESP Production

The Dual ESP system deploys two electrical submersible pumps (ESPs) at different depths in a wellbore. Each zone is isolated so that the operator can monitor and control production independently. The system includes all packers, Y-tool or other splitting equipment, and pumping, downhole power, motor, and auxiliary components. The Dual ESP system is available in two configurations:

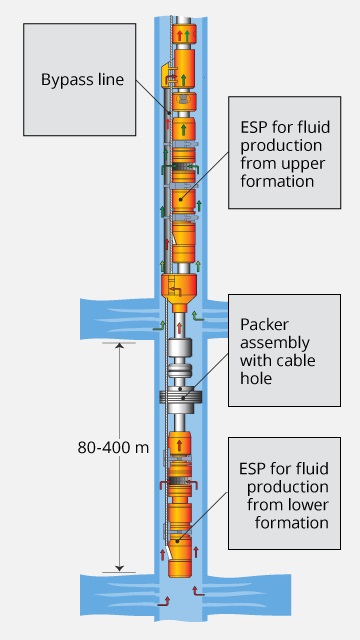

- The separate-zone configuration places one ESP deeper in the well at one production zone and the other ESP higher in the well at a second production zone. An isolation packer between the ESPs enables full control and monitoring of each zone.

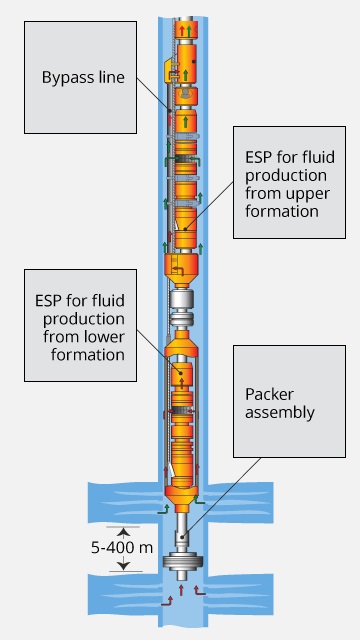

- The same-zone configuration places both ESPs in a single zone, but the intake for the bottom ESP is mounted on production tubing up to 16 ft (5 m) lower in the wellbore, enabling it to reach a lower production zone. An isolation packer is set around the production tubing extension to ensure zonal isolation.

Injecting While Producing

The injecting-while-producing system uses one downhole pump to force fluid into one formation and an ESP to produce fluid from a second zone. This single-bore water-flood solution maintains downhole pressure to reduce cycling and recover more oil in struggling wells. The injecting-while-producing system can inject from an upper zone and produce from the lower with the aid of isolation packers, or it can inject in the bottom zone and produce from a zone higher in the well.

TECHNICAL CHARACTERISTICS

Dual ESP Separate-Zone Configuration

|

Casing OD |

Upper ESP system |

Lower ESP system |

||||

|

Series |

System OD |

Bypass tubing (OD/ID) |

Flow rate capacity |

Series |

Flow rate capacity |

|

|

5¾ in. |

319 |

4.80 in. |

1.65 / 1.02 in. |

1,760 bbl/day |

362, 406 |

4,400 bbl/day |

|

146 mm |

3 |

122 mm |

42/26 mm |

280 m3/d |

5, 5A |

700 m3/d |

|

6⅝ in. |

319 |

5.59 in. |

2.20 / 1.57 in. |

1,760 bbl/day |

362, 406 |

4,400 bbl/day |

|

168 mm |

3 |

142 mm |

56/40 mm |

280 m3/d |

5, 5A |

700 m3/d |

|

7 in. |

319 338 |

5.98 in |

2.20 / 1.57 in. |

1,760 bbl/day 2,200 bbl/day |

362, 406 |

4,400 bbl/day |

|

178 mm |

3 4 |

152 mm |

56/40 mm |

280 m3/d 350 m3/d |

5, 5A |

700 m3/d |

|

9⅝ in. |

up to 406 |

8.27 in |

2.87 / 1.97 in. |

5,030 bbl/day |

535 |

up to 6,290 bbl/day |

|

245 mm |

up to 5A |

210 mm |

73/50 mm |

800 m3/d |

7A |

1000 m3/d |

Dual ESP Same-Zone Configuration

|

Casing OD |

Upper ESP system |

Lower ESP system |

|||||

|

Series |

System OD |

Bypass tubing (OD/ID) |

Flow rate capacity |

Series |

ESP Shroud (OD/ID) |

Flow rate capacity |

|

|

5¾ in. |

319 |

4.80 in. |

1.65 / 1.02 in. |

1,760 bbl/day |

319 |

4.76 / 3.94 in. |

2,200 bbl/day |

|

146 mm |

3 |

122 mm |

42/26 mm |

280 m3/d |

3 |

121/100 mm |

350 m3/d |

|

6⅝ in. |

319 |

5.59 in. |

2.20 / 1.57 in. |

1,760 bbl/day |

319 |

4.76 / 3.94 in. |

2,200 bbl/day |

|

168 mm |

3 |

142 mm |

56/40 mm |

280 m3/d |

3 |

121/100 mm |

350 m3/d |

|

7 in. |

319 338 |

5.98 in |

2.20 / 1.57 in. |

1,760 bbl/day 2,200 bbl/day |

319 338 |

4.76 / 3.94 in. 5.51 / 4.61 in. |

1,760 bbl/day 2,200 bbl/day |

|

178 mm |

3 4 |

152 mm |

56/40 mm |

280 m3/d 350 m3/d |

3 4 |

121/100 mm 140/100 mm |

350 m3/d 350 m3/d |

|

9⅝ in. |

up to 406 |

8.27 in |

2.87 / 1.97 in. |

5,030 bbl/day |

up to 406 |

7.48 / 5.51 in. |

up to 5,030 bbl/day |

|

245 mm |

up to 5A |

210 mm |

73/50 mm |

800 m3/d |

up to 5A |

190/140 mm |

up to 800 m3/d |