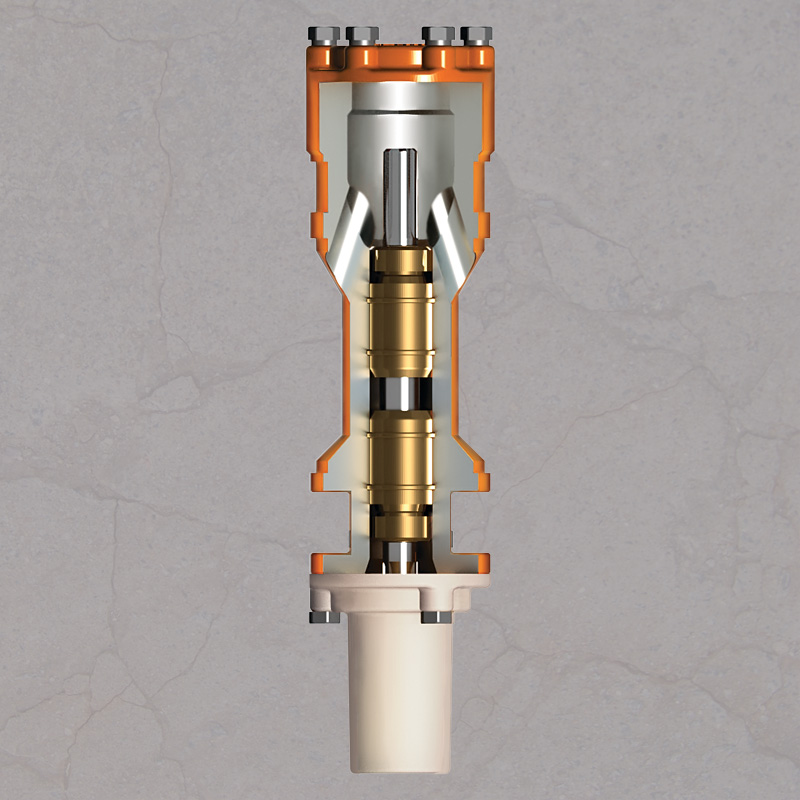

ESP INTAKE

The intake on an ESP enables fluid to enter the system. In wells, an intake does nothing more than provide a gap in the production string that channels fluid from the reservoir into the pump.

BENEFITS

A broad range of sizes enables you to optimize fluid intake for well type and condition

A protective chromium-nickel stainless steel liner provides erosion resistance

Optional corrosion-resistant modifications can be made to extend intake life in sour wells

applications

- Conventional and unconventional wells

- Wells using ESPs for production

capabilites

- Available in 272 (69 mm), 319 (81 mm),

338 (86 mm), 362 (92 mm), 406 (103 mm),

460 (117 mm), and 535 (136 mm) series - Flowrates up to 12,600 bbl/d (2000 m3/d)

features

- A broad range of sizes enables you to optimize fluid intake based on well type and condition

- Optional corrosion-resistant modifications can be made to extend runlife in sour wells

TECHNICAL CHARACTERISTICS

|

Outer Diameter |

Length |

Weight |

Nominal flow rate |

Max inlet GOR |

|

2.72 in. |

0.78 ft |

11 lb |

1,900 bbl/d (@60Hz) |

25% |

|

69 mm |

0.24 m |

5 kg |

300 m3/d (@50Hz) |

|

|

3.19 in. |

0.78 ft |

13 lb |

2,800 bbl/d (@60Hz) |

|

|

81 mm |

0.24 m |

6 kg |

450 m3/d (@50Hz) |

|

|

3.38 in. |

0.77 ft |

13 lb |

3,150 bbl/d (@60Hz) |

|

|

86 mm |

0.24 m |

6 kg |

500 m3/d (@50Hz) |

|

|

3.62 in. |

0.93 ft |

20 lb |

5,000 bbl/d(@60Hz) |

|

|

92 mm |

0.28 m |

9 kg |

800 m3/d(@50Hz) |

|

|

4.06 in. |

0.93 ft |

24 lb |

6,300 bbl/d(@60Hz) |

|

|

103 mm |

0.28 m |

11 kg |

1,000 m3/d(@50Hz) |

|

|

4.60 in. |

1.05 ft |

33 lb |

11,300 bbl/d(@60Hz) |

|

|

117 mm |

0.34 m |

15 kg |

1,800 m3/d(@50Hz) |

|

|

5.35 in. |

1.21 ft |

55 lb |

12,600 bbl/d(@60Hz) |

|

|

136 mm |

0.37 m |

25 kg |

2,000 m3/d (@50Hz) |

Dealing with gas

One of the most common problems in ESP production is dealing with gas in the reservoir. Because ESPs are designed to pump fluid, excess gas can cause overheating and gas locking—where a gas pocket fills the pump and prevents fluid from entering the system.

Novomet follows this basic order of escalation when dealing with gas-prone reservoirs:

- Use an advanced gas handler to force up to 50% free gas into solution so it can be pumped to the surface with fluid

- Use a multiphase pump to force both fluid and up to 75% free gas through the system

- Use a gas separator to remove up to 85% free gas from the intake and vent it to the annulus