IN DIFFICULT DOWNHOLE COMPLETIONS

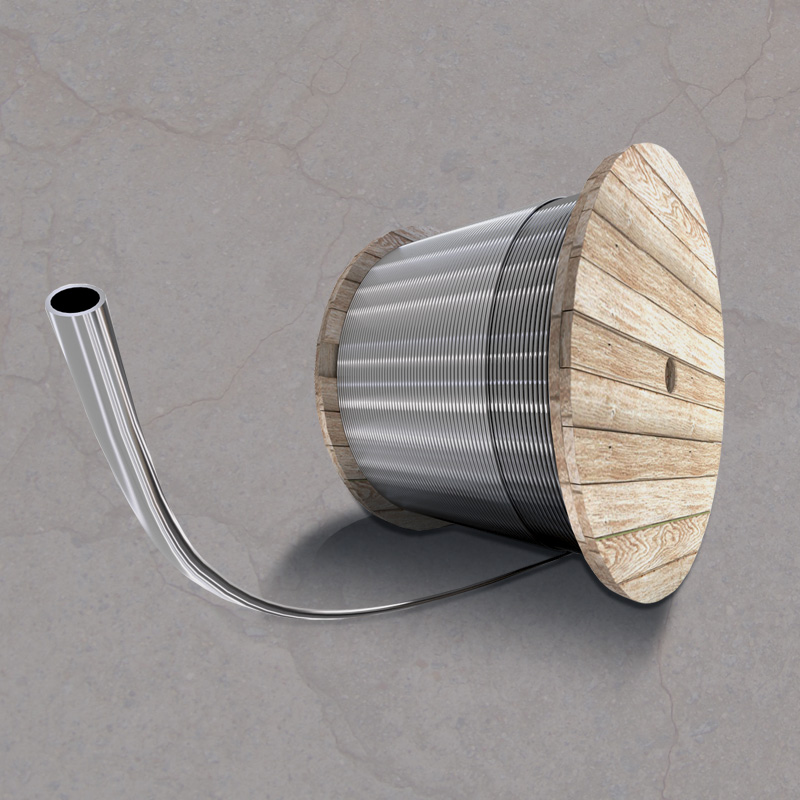

HYDRAULIC CONTROL LINE

The hydraulic control line, also known as a chemical injection line, is a small-diameter line, usually ⅛ in. (32 mm) or ⅝ in. (16 mm), used to execute tool recovery, perform chemical injection, and operate downhole completions equipment such as surface-controlled subsurface safety valves (SCSSV). When used with an SCSSV, the hydraulic control line maintains constant pressure to keep the safety valve open. If a leak occurs, pressure in the control line drops, enabling the safety valve to snap closed and prevent low of well control.

Strong, corrosion-resistant, and reliable, these lines meet all ASTM standards and operate effectively in difficult environments to maintain production flow. Lines are pressure-tested and certified before deployment. They are available for any length well.

BENEFITS

Safely operate downhole completion equipment to maintain optimal flow in challenging environments

Keep up performance and avoid costly interventions in difficult wells and tool recovery operations

Strong, virtually seamless lines exploit the most difficult conditions to maximize production

applications

- Subsea and downhole applications

- Harsh environments, such as high-pressure, high-temperature (HPHT) wells and corrosive conditions

- Tool recovery operations

- Chemical injection

- Annular gas venting

- Capillary pressure monitoring

capabilites

- Control of subsurface safety valves

- Hydraulically controlled sliding sleeves

features

- Lines are welded and drawn to homogenize the seam weld for a better sealing surface, rounder OD, and an mproved external surface finish

- Orbital welds are used to join lengths of seamless coil to achieve smooth, strong tube lengths suitable for any well application

- Seamless tubing for orbital welds is also available

SIZES AVAILABLE

TUBE MATERIALS

- 316L Stainless steel

- A825 Alloy

- A825 Alloy enhanced properties

- Duplex 2205/2507

- Alloy 625

AFTER WELDING

After welding, the line is drawn through a reduction die and reworked externally to homogenize the seam weld. By drawing through a die, the line has an improved sealing surface, a truly round OD, and an improved external surface finish. A metal billet is extruded into a tube and drawn to finished size. Strong, error-free orbital welds join the lengths of seamless coil together for the desired tube lengths.

OTHER SIZES

Other sizes and options can be requested.

|

⅛ in. |

0.125 x 0.028 in. (3.18 x 0.71 mm) |

|

0.125 x 0.035 in. (3.18 x 0.89 mm) |

|

|

¼ in. |

0.25 x 0.035 in. (6.35 x 0.89 mm) |

|

0.25 x 0.049 in. (6.35 x 1.25 mm) |

|

|

0.25 x 0.065 in. (6.35 x 1.65 mm) |

|

|

⅜ in. |

0.375 x 0.035 in. (9.53 x .89 mm) |

|

0.375 x 0.049 in. (9.53 x 1.25 mm) |

|

|

0.375 x 0.065 in. (9.35 x 1.65 mm) |

|

|

½ in. |

0.5 x 0.049 in. (12.7 x 1.25 mm) |

|

0.5 x 0.065 in. (12.7 x 1.65 mm) |

|

|

0.5 x 0.083 in. (12.7 x 2.11 mm) |

|

|

⅝ in. |

0.625 x 0.049 in. (15.88 x 1.25 mm) |

|

0.625 x 0.065 in. (15.88 x 1.65 mm) |

|

|

0.625 x 0.083 in. (15.88 x 2.11 mm) |

PARAMETER GUIDE

|

|

½ in. (12.7 mm) THREAD DOWN |

1 in. (25.4 mm) THREAD DOWN |

|

General Information |

||

|

Product functionality |

Annular Vent Valve |

Annular vent valve |

|

Conveyance method |

Mounted on ESP Packer |

Mounted on ESP packer |

|

Materials |

AISI 4140 (80Ksi, 22HRC Max.) |

AISI 4140 (80Ksi, 22HRC Max.) |

|

Service |

NACE MR0175 / H2S15156 |

NACE MR0175/H2S15156 |

|

O-ring material |

HNBR / VITON |

HNBR/VITON |

|

Upper connection |

¼ in. (6 mm) NPT Box |

¼ in. (6 mm) NPT Box |

|

Lower connection |

½ in. (12.7 mm) NPT Box |

1 in. (25.4 mm) NPT Box |

|

Performance Data |

||

|

Pressure rating, internal |

5,000 psi (352 kg/cm) |

5,000 psi (352 kg/cm) |

|

Minimum internal flow area |

0.196 in.2 (5 mm2) |

0.196 in.2 (5 mm2) |

|

Start to open pressure |

2,600 psi (183 kg/cm) +/- 10% |

2,600 psi (183 kg/cm) +/- 10% |

|

Fully opened pressure |

3,000 psi (211 kg/cm) +/- 10% |

3,000 psi (211 kg/cm) +/- 10% |

|

Fully closed pressure |

1,000 psi (70.32 kg/cm) +/- 10% |

1,000 psi (70.32 kg/cm) +/- 10% |

|

Maximum OD |

1.6 in. (41 mm) |

1.6 in. (41 mm) |

|

Approximate overall length |

24 in. (610 mm) |

24 in. (610 mm) |

|

Temperature rating |

122–257°F (50–125°C) |

122–257°F (50–125°C) |