COLIBRI CABLE-DEPLOYED RIGLESS ESP

The Colibri rigless ESP system requires only reinforced carrying cable to be deployed and retrieved. All operations can be conducted on modified slickline equipment. There is no need for a rig, making it a truly rigless electrical submersible pumping (ESP) system. Saving both time and money, cable deployment enables operators to resume production quickly without having to kill the well. The short-term result is a decrease in deferred production without having to wait and pay for the rig required in standard ESP operations. The long-term implications include eliminating rigs from ESP installations altogether, reducing risk, and lowering the number of personnel required to install ESPs.

BENEFITS

Simple cable deployment eliminates the cost, time, and personnel needed for a rig

Installing under live well conditions reduces safety/environmental risk and cuts production downtime

Removing the risks associated with offshore ESPs enables greater production and recovery

Rig-deployed ESPs take time

The offshore ESP conundrum

In offshore and remote wells, the days it takes to kill the well, pull the tubing, replace the ESP, and run an ESP back in hole can be costly. In fact, the costs for installing or replacing an ESP in an offshore well are often so high that the operation is not economically viable. In too many cases, operators are leaving hydrocarbons behind because they don’t have an economical way to produce their wells.

Just getting a rig onsite can be a challenge and can take days or weeks. Every day spent waiting translates into a day of deferred production, potentially costing operators hundreds of thousands—or even millions—of dollars.

The minute a tubing-deployed ESP fails, it starts costing an operator production revenue. The time it takes to mobilize a rig, change out the ESP, and get the well back online causes major lost production revenue to operators who use ESPs.

The fact is that rig-deployed ESP technology—intended to enhance production—can actually be a liability if the ESP fails. In many offshore wells, operators have traditionally shied away from using ESPs because they simply do not provide enough reward to justify the associated risks.

Lose the rig, change the economics

The Colibri cable-deployed rigless ESP system eliminates the greatest risks associated with using ESPs in high-value and deep offshore wells. It is deployed and retrieved using reinforced carrying cable, eliminating the need for a rig altogether.

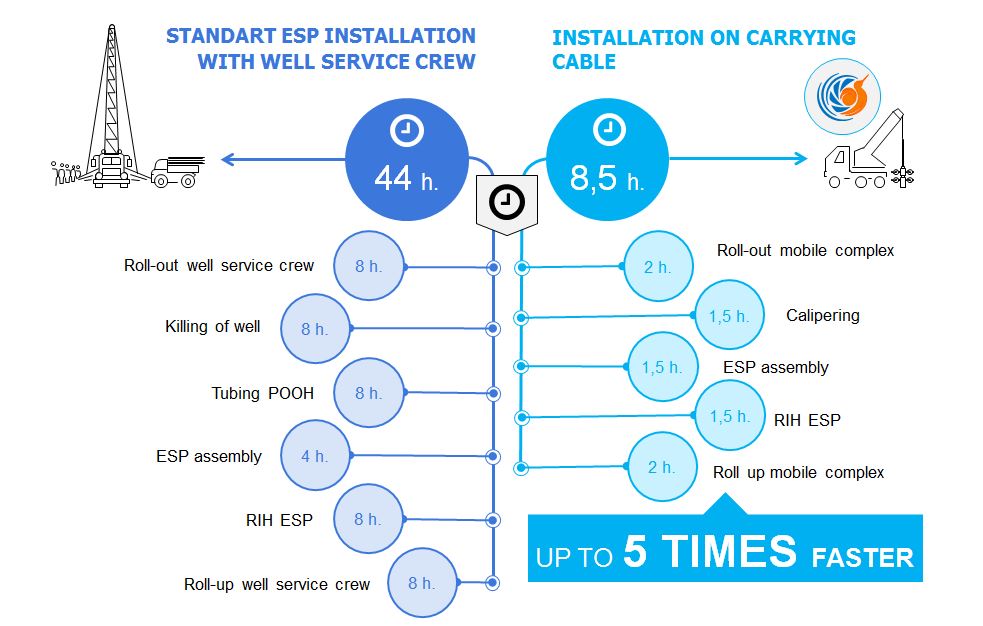

Recent results indicate that Colibri installation is up to five times faster than a typical rig-deployed ESP installation on land. As illustrated in the graphic below, the economic advantages of the Colibri rigless ESP increase dramatically in offshore and remote wells.

The process is fast, reliable, and can be carried out under live-well conditions—eliminating the need to kill the well. The thru-tubing ESP is deployed through a surface lubricator and lowered inside the existing production tubing. The Colibri system can be easily retrieved using only the cable. So, it can be used temporarily to keep production flowing and then removed when a replacement ESP arrives. Or it can be left in hole permanently as the replacement, providing a way to extend the economic life of wells that would otherwise be plugged and abandoned due to workover and rig costs.

This technology also reduces health and safety risks. Instead of the full crew needed to run a rig during tubing-deployed ESP replacement, the Colibri system can be deployed with only three or four onboard personnel.

applications

- Conventional wells

- Offshore and remote wells

- Brown and green fields

- Well unloading and testing

- Thru-tubing ESP production

- Temporary and permanent production

- Cost-effective replacement for gas lift in offshore wells

capabilities

- Flowrates up to 3,145 bbl/d (500 m3/d)

- Fluid head up to 9,840 ft (3000 m)

- Temperatures up to 355°F (180°C)

features

- Cable-deployed, cable-retrievable thru-tubing ESP design enables running through the existing wellhead without killing the well

- Modified slickline equipment eliminates the rig, reduces the footprint, and cuts the number of required personnel

- The system produces through existing tubing, reducing risk, time, and cost

- The system can be used temporarily to keep production flowing, or remain downhole permanently

- Rigless ESP design includes packers, subsurface safety valves, and other required completions tools

- An optional thru-tubing ESP saddle can be installed during completions operations, giving operators the flexibility to quickly and easily deploy the Colibri system at any time during the well’s life

The Novomet advantage

Get the size you need, from 2.72-in. (69-mm) systems up to 7.40-in. (188-mm) systems. We offer slimline designs with reliable 3.19-in. (81 mm) motors sized to make deployment in 4-in. casing a snap.

Improve runlife with an option to place the axial thrust bearing in the motor protector instead of in the pump, and with a compression design that resists abrasion. Bearings and shaft materials use corrosion-resistant steels and alloys to improve longevity in corrosive wells.

We offer various pump configurations:

- Centrifugal-vortex

- Inverted centrifugal-vortex

- Centrifugal

- Inverted centrifugal

- Centrifugal-axial

- Openstage designs for high gas

TECHNICAL CHARACTERISTICS

|

|

Max OD |

Max string length |

Max capacity |

Max head |

|

217 series |

2.17 in. 55 mm |

82 ft 25 m |

1,132 BPD 180 m3/day |

6,560 ft 2000 m |

|

272 series |

2.72 in. 68 mm |

90 ft 27.5 m |

1,758 BPD 280 m3/day |

11,480 ft 3500 m |

|

319 series |

3.19 in. 81 mm |

105 ft 32 m |

4,835 BPD 770 m3/day |

9,350 ft 2850 m |

MOTOR CHARACTERISTICS

|

|

Max motor power |

Motor efficiency |

RPM |

Nominal RPM |

Max reservoir temperature |

|

217 series |

70 kW 94 hp |

85% |

6,000–10,000 |

8,500 |

300°F 110°C |

|

272 series |

70 kW 94 hp |

85% |

6,000–10,000 |

8,500 |

355°F 130°C |

|

319 series |

210 kW 285 hp |

90% |

6,000–10,000 |

8,500 |

355°F 130°C |

Completions equipment included

Novomet also offers downhole packers, nipples, and subsurface safety valves needed to maintain well integrity and ensure reliable rigless ESP installation and operation.

Rigless ESP benefits

- Eliminates the need for a rig

- Requires minimal downtime for installation

- Eliminates need to kill the well and pull tubing

- Deploys through existing wellhead

- Provides lift in wellbores with restrictions or limitations

- Includes downhole packers and subsurface safety valves

Leading the rigless ESP race

The Colibri rigless ESP has the potential to change the way ESPs are deployed across the industry. Installing thru-tubing ESPs on cable offers time, cost, and safety advantages that will likely make standard tubing-deployed systems a thing of the past. Some new well designs now include a saddle for the Colibri system that is installed with the completion for future use. This enables easy access to install, replace, and remove Colibri systems under live-well conditions throughout the life of the well with no need for rigs or rig personnel. By giving operators the flexibility to add or remove the ESP at any time, this technology eliminates the greatest economic risks associated with using ESPs offshore and extends the economic life of wells that would otherwise be plugged and abandoned.

Colibri Cable-Deployed ESP CASE STUDIES